Umshini wokuhlunga umbala nobhontshisi wombala

Isingeniso

Isetshenziselwa irayisi kanye paddy , ubhontshisi kanye pulses , ukolweni , ummbila , imbewu ye-sesame nobhontshisi wekhofi nabanye.

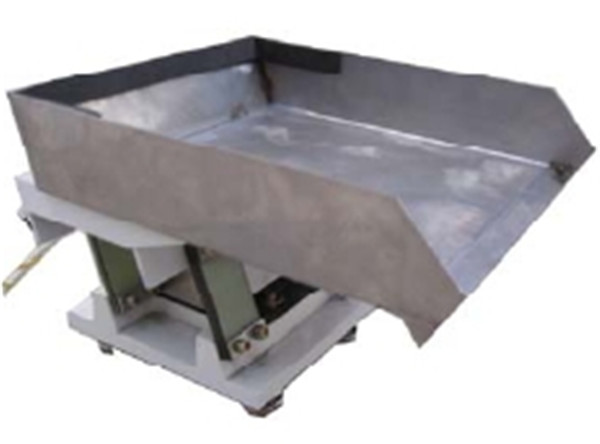

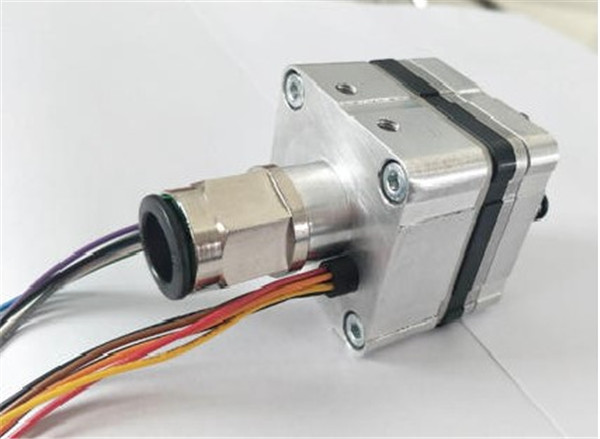

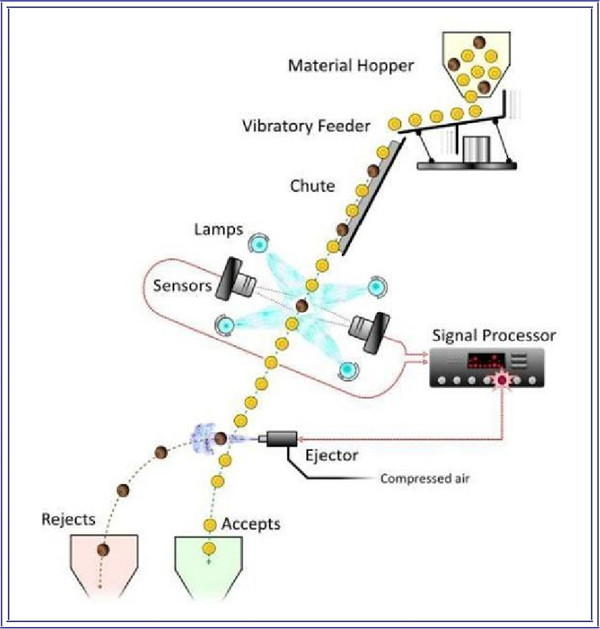

Idivayisi yokudlidliza-isidlidlizi

Ukondla indlela yokudlidliza, into ekhethiwe iyanyakaziswa futhi idluliselwe endaweni edlula umgwaqo we-hopper. Isistimu yokulawula ilawula inani elikhulu lokudlidliza kwe-vibrator ngokusebenzisa ukulungiswa kobubanzi be-pulse Encane, ukuze kuzuzwe ukulungiswa kokugeleza kwawo wonke umshini.

Ikhipha isiteshi sedivayisi ye-chute

Indawo lapho okubalulekile kusheshisa khona phansi ukuze kuqinisekiswe ukuthi impahla engena egunjini lokuhlunga ihlukanisiwe Indwangu iyafana futhi ijubane liyahambisana, ukuze kuqinisekiswe umphumela wokukhetha umbala.

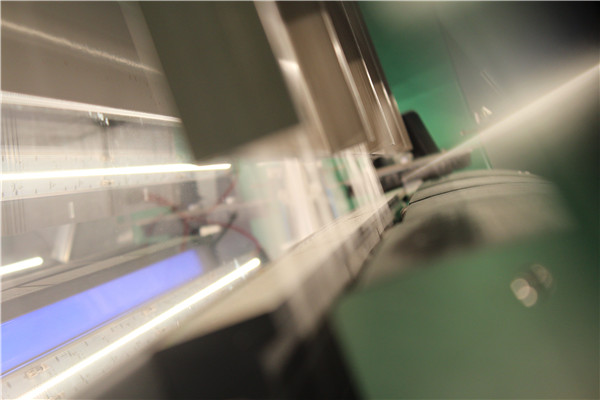

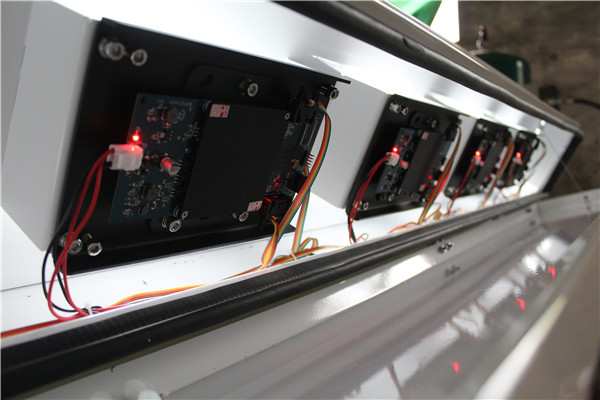

Igumbi lokuhlunga lesistimu yokubona

Ukuqoqwa kwezinto kanye nedivayisi yokuhlunga, umthombo wokukhanya, idivayisi yokulungisa ingemuva, i-CCD

Yakhiwe idivayisi yekhamera, iwindi lokubuka nesampula, kanye nedivayisi yokususa uthuli.

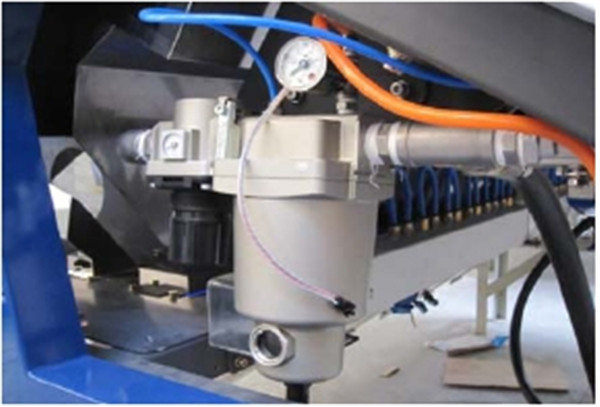

I-Nozzle system-spray valve

Lapho isistimu ibona into ethile njengomkhiqizo onesici, i-valve yesifutho ikhipha igesi ukuze iqede Impahla. Isithombe esingezansi sibonisa imibhobho ebonakala kalula emshinini.

Lawula ibhokisi lokulawula elisebenza ngogesi

Lo mnyango Uhlelo lunomthwalo wemfanelo wokuqoqa ngokuzenzakalelayo, ukukhulisa, kanye nokucubungula amasiginali kagesi wesithombe, nokuthumela imiyalo yokushayela i-valve yesifutho ngengxenye yokulawula ukuze kufutha ukucindezelwa Umoya uqhumisa ukwenqatshwa, uqedele umsebenzi wokukhetha umbala, futhi ufeza inhloso yokukhetha.

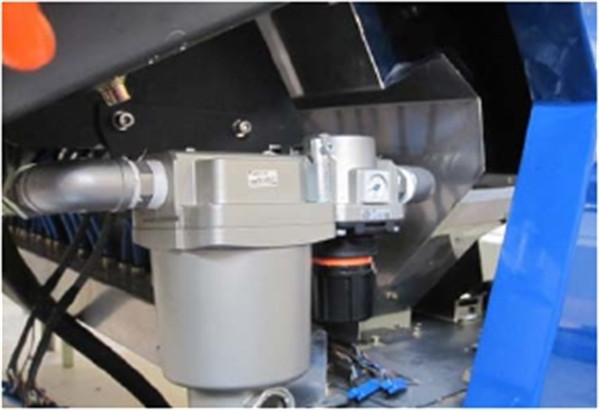

Uhlelo lwegesi

Itholakala ohlangothini lwesobunxele nakwesokudla somshini, inikeza ukuhlanzeka okuphezulu komoya ocindezelwe kuwo wonke umshini.

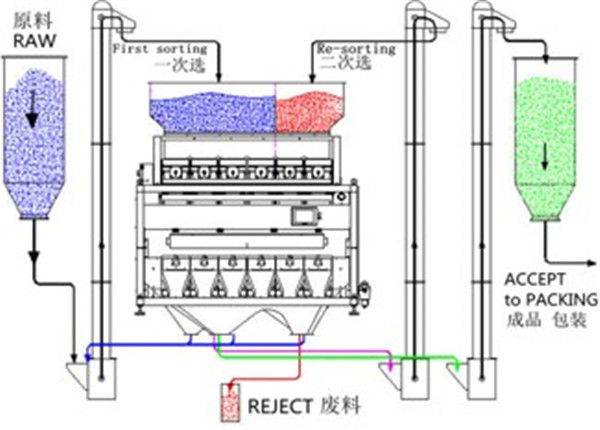

Isakhiwo Sonke Somshini

Ngemuva kokuthi izinto zifake isihlungi sombala kusuka phezulu, ukuhlelwa kombala kokuqala kwenziwa. Izinto ezifanelekayo ziyimikhiqizo eqediwe. Izinto ezikhethiwe zokwenqaba zithunyelwa kusiteshi sesibili sokukhetha imibala ngumsebenzisi ngedivayisi yokuphakamisa ukuze kukhethwe umbala wesibili. Izinto ezisetshenziswayo nezinto ezifanelekayo zokuhlunga kombala wesibili zifaka ngokuqondile izinto zokusetshenziswa noma zibuyele kweyokuqala ngedivayisi yokuphakamisa elungiselelwe umsebenzisi . Ukuhlunga kwesibili kwenzelwa ukuhlunga kombala wesibili, futhi izinto ezinqatshiwe zokuhlunga kombala wesibili ziyimikhiqizo yemfucuza. Inqubo yokuhlunga kombala wesithathu iyafana

Isihlungi sombala Ingxoxo egelezayo esebenzayo

Lonke uhlelo

Imininingwane iyakhombisa

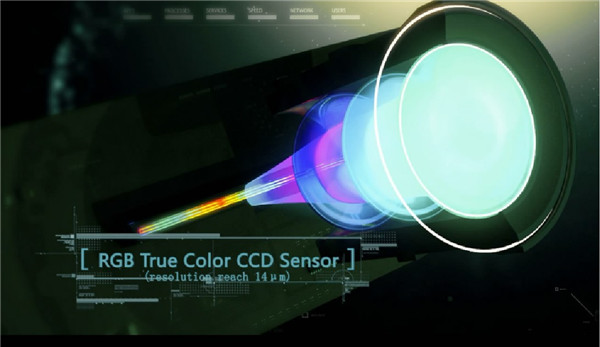

uhlelo lokubamba isithombe se-CCD sombala weqiniso

Ivalve ye-Solenoid esezingeni eliphezulu

I-Cpu Engcono Kakhulu Yesistimu Yonke

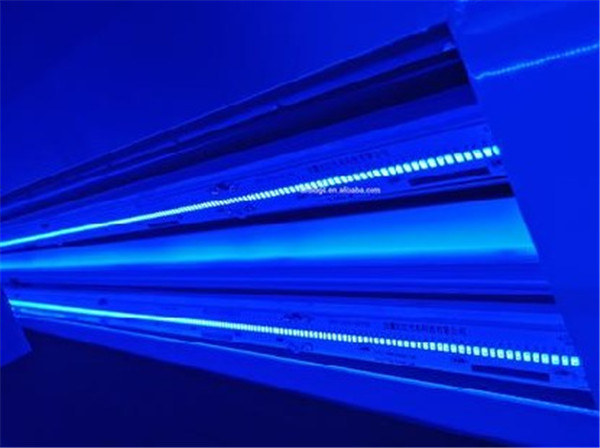

Ukukhanya kwe-LED

Ukucaciswa kobuchwepheshe

| Imodeli | Ama-ejector (ama-pcs) | Amaqanda (ama-pcs) | Amandla (Kw) | I-Voltage(V) | Ingcindezi Yomoya (Mpa) | Ukusetshenziswa Komoya (m³/min) | Isisindo(Kg) | Ubukhulu (L*W*H,mm) |

| C1 | 64 | 1 | 0.8 | I-AC220V/50Hz | 0.6~0.8 | < 1 | 240 | 975*1550*1400 |

| C2 | 128 | 2 | 1.1 | I-AC220V/50Hz | 0.6~0.8 | < 1.8 | 500 | 1240*1705*1828 |

| C3 | 192 | 3 | 1.4 | I-AC220V/50Hz | 0.6~0.8 | <2.5 | 800 | 1555*1707*1828 |

| C4 | 256 | 4 | 1.8 | I-AC220V/50Hz | 0.6~0.8 | <3.0 | 1000 | 1869*1707*1828 |

| C5 | 320 | 5 | 2.2 | I-AC220V/50Hz | 0.6~0.8 | <3.5 | 1 100 | 2184*1707*1828 |

| C6 | 384 | 6 | 2.8 | I-AC220V/50Hz | 0.6~0.8 | <4.0 | 1350 | 2500*1707*1828 |

| C7 | 448 | 7 | 3.2 | I-AC220V/50Hz | 0.6~0.8 | <5.0 | 1350 | 2814*1707*1828 |

| C8 | 512 | 8 | 3.7 | I-AC220V/50Hz | 0.6~0.8 | <6.0 | 1500 | 3129*1707*1828 |

| C9 | 640 | 10 | 4.2 | I-AC220V/50Hz | 0.6~0.8 | <7.0 | 1750 | 3759*1710*1828 |

| C10 | 768 | 12 | 4.8 | I-AC220V/50Hz | 0.6~0.8 | <8.0 | 1900 | 4389*1710*1828 |

Imibuzo evela kumakhasimende

Kungani sidinga umshini wokuhlunga imibala?

Manje njengoba izidingo zokuhlanza ziya ngokuya ziba phezulu, izihlungi zemibala ziya ngokuya zisetshenziswa embonini yokugaya usesame nobhontshisi, ikakhulukazi imboni yokugaya ubhontshisi wekhofi kanye nesikhungo sokugaya irayisi . Isihlungi sombala singasusa ngempumelelo izinto ezinemibala ehlukene kubhontshisi wokugcina wekhofi ukuze sithuthukise ubumsulwa.

Ngemuva kokucubungula nge-sorter yombala ubumsulwa bungafinyelela ku-99.99%. Ukuze yenze okusanhlamvu kwakho nelayisi kanye nobhontshisi wekhofi kubaluleke kakhulu.